DSX is the leader in the field of Tribology: The Science of Friction and Drag Reduction

DSX Extra

- DELIVERS unequaled friction protection at extremely high or low temperatures.

- PROTECTS high bearing surfaces from cold start-up stress pressures.

- EXTENDS engine and parts life under all operating conditions especially at red line RPM’s.

- REDUCES wear while delivering faster reaction, cooler running and more power.

- IMPROVES fuel economy as much as 15%, based on customer reports.

- REDUCES exhaust emissions as much as 15%.

- PROVIDES shielded protection against wear, corrosion, carbonization and oxidation.

- SUPPORTS universal viscosity with all synthetic and conventional petroleum oils and greases.

- EMBEDS permanently in the metal surface asperities without changing tolerances of bearings, rings or pistons.

- CONTAINS no hazardous hydrocarbons or chlorofluorocarbons (CFC’s).

- ENVIRONMENTALLY SAFE to handle, ship, store and dispose of.

The DSX Products are based on embedded particle technology. All DSX Products modify friction. Basically, the fluoropolymer particles fill the voids in the surface of the materials creating a better fit and finish. It is this better fit and finish that allows for a more complete burn of the fuel with a corresponding reduction in discharge/emissions and improved fuel economy. The applications for the DSX Products are many.

Regarding trucks, trains, boats and construction equipment the applications are primarily power train; engine, transmission and drive axles. There are other applications also in bearings and gears. Engines. With engines, DSX Extra is applied with new oil at the start of a typical service cycle. Experience has shown for the first application, ten percent DSX Extra is added to the engine oil. For subsequent oil changes, DSX Extra is applied at the ratio of five percent. Transmissions. DSX Extra is applied to the transmissions fluid at a ratio of ten percent. Drive axles. DSX Extra is applied to the drive axle lube at a ratio of ten percent. Note: In all cases, we are working with existing conditions of the engine, transmission and drive axles. We have found in some cases a very quick response, as in by the end of the second week. In other cases, improvement has been slow and steady.

It is our assumption that this phenomenon is directly related to the condition of the metal at the start of the test. Examples. One customer started with one quart of DSX Extra in each drive axle in May of 2007. His vehicle, a ’07 Peterbilt, has gauges to monitor temperature in the transmission and drive axles. He observed no change in temperature until adding another quart of DSX Extra in July of 2007. He called us the following Tuesday to report a temperature reduction. By the end of the week, the temperature was lower by 15 Deg F to 20 Deg F. Today, the end of May 2010, the temperature remains lower by 15 Deg F to 20 Deg F. In another case, a customer added two quarts to each drive axle and found a 10 Deg F to 15 Deg F reduction in temperature and was very pleased.

A year later he contacted us to ask if he should do it again. I asked if there was any change in temperature and he replied “the temperature remains 10 Deg F to 15 Deg F lower than before DSX Extra, essentially no change”. I suggested adding more DSX Extra to each drive axle. He did and had a temperature reduction of an additional 10 Deg F. DSX Extra works with all lubricants. It is important to understand that our DSX Products are not working to improve on the lubricant. All major oil companies make excellent products. The DSX products are working to improve the fit and finish of the metal so the lubricant can do its job better. Your existing lubricant is a carrier for the DSX Product.

DSX PRODUCTS: STANDARDS AND REQUIREMENTS

- DSX EXTRA Oil Additive and DSX oil based products meet worldwide specifications including MIL-L-2104E, MIL-L-46152E, API SCICD, and European CCMC-G4~ 0-5; P1)2 and JASO wear tests.

DSX products are fully compatible with all conventional and synthetic oils. - DSX products repel sand, debris, rain, snow, ice and salt; and are non-flammable, nontoxic, non-corrosive, and contain no petroleums.

- DSX products are a 100% blend of synthetics that are environmentally safe.

- DSX products meet both high and low temperature requirements in the full spectrum of motor vehicle usage: land, air and water; on the road, on the track, on the strip, in the Arctic, Jungle, Desert or at Sea; at high altitudes or below sea level.

- DSX is a concentrate of Premium Grade Fluoropolymers of submicron size that enhances all lubricants and provides Superior embedded particle lubrication and protection.

DSX EXTRA AND ENGINE VARNISH

Recently one of our customers reported on the rebuild of an engine. The rebuild was done by our customer with the assistance of the owner of a high tech rebuild facility. The engine was a high temperature high output engine. DSX Extra had been in the engine for five service cycles. The following information was prepared by the owner of the rebuild facility: “From my years in the power generation industry (specializing in filtration and lubrication) I have been made very aware of the ongoing problem of varnish build up on metallic surfaces such as bearings, valves and actuators.

For a very long time, the varnish problem seemed to be an unfortunate by product of heat, oil and friction. Metallic varnish has long been known to be caused by sub micron size particles that cannot be filtered via conventional media and collect in tiny voids on any surface. Upon dis-assembly of an engine to inspect and measure the effects of DSX Extra, the near absence of varnish was quite surprising.

While further testing is being conducted to quantify these results, preliminary findings show that DSX Extra’ fluorocarbon displaces existing varnish and inhabits the void preventing and at the same time diminishing varnish build up in high temp or high friction oil applications.” Garry Ratliff, BSME, ASQC CMI

MEMORANDUM DSX EQUIPMENT TECHNOLOGIES LLC

18 Feb 2012

To: Our customers

From: Lee Lippert

Ref: DSX Products and temperature reduction (Arrhenius Rate Rule)

The Arrhenius Rate Rule states that for every 18 Deg F (10 Deg C) increase in oil temperature, oil life is cut in half. Conversely, the reduction in temperature of 18 Deg F essentially doubles the life of the oil. A reduction in temperature of 36 Deg F doubles the life of the lubricant yet again. Basically this is an indication of the effect of temperature on the rate of lubricant degradation.

Technically, heat increases the collision rate of molecules and the activation energy of the reaction. Furthermore, the presence of contaminants such as water and metal particles in the lubricant can speed up the process, increasing the energy activation. The baseline for these calculations seems to be above 150 Deg F according to some published data and higher with other data. The end result in all cases we researched seems to be similar.

What is the relationship between the DSX products, temperature reduction and the useful life of lubricants? One of our customers reported a temperature reduction of 20 Deg F in the drive axles of the truck he drives- an ’07 Peterbilt with an ’06 CAT C15 engine after adding our DSX Extra to the gear lube. Details are available as to application. Based on that information he applied enough DSX Extra to the transmission fluid and engine oil until he reached 20 Deg F temperature reduction. All of his trucks have temperature gauges. In all cases, he applied DSX Extra until the temperature reduction of 20 Deg F was attained in engine, transmission and drive axles.

There is/was no specific reason as to the use of 20 Deg F as the guideline. Recently he changed the transmission fluid because he thought it a good idea since he normally changed transmission fluid 125,000 miles earlier. He reported the used transmission fluid had minimal discoloration and no odor. He volunteered that he could easily have gone another 100,000 miles or more. The trucks owned by this customer have more than 500,000 miles with DSX Extra. Today his lubricant temperature for drive axles and transmission is 150 Deg F to 155 Deg F.

Another customer started with DSX Extra in the engine and gradually applied it to the transmission and drive axles. He has approximately 700,000 miles of experience with DSX Extra. This customer observed his temperature gauges were not moving, or barely moving, so he thought they may have failed. He had them checked at the service center he has used for years. The temperature gauges are working fine. This suggests temperature reduction in excess of 30 Deg F. In this case, the customer changed oil at 18,000 miles when he started with DSX Extra. Based on oil analyses, feel, look and smell he now changes oil at 35,000 miles but thinks he could go much further.

These customers work in different parts of the country with different trucks and different power set ups. They have two things in common; (1) they both use DSX Extra and have for years and many miles and (2) they both have temperature gauges. Admittedly, this is a small population. However, finding trucks with temperature gauges is not always easy.

TMC RP – 1102 (SAE J1321) Type II Fuel Consumption Test

Abstract:

The purpose of this testing program was to evaluate the performance of a lubricant additive known as DSX Extra. The product claims to derive its benefit from the addition of friction reducing flouropolymer particulates to lubricating fluids. In order to facilitate testing, DSX Extra was added to all driveline components, engine, transmission and tractor drive axles.

The TMC / SAE Type II test procedure was used to evaluate the product’s effectiveness in improving the fuel economy of Class 8 heavy trucks. Testing was conducted by researchers at the PAVE Research Institute between the dates of April 19 and June 12, 2007 on the Pavement Test Track at Auburn University. The following data were collected after three progressive stages of product use: • 0.1% improvement in fuel economy after oil change with treatment and 8,219 miles; • 1.6% improvement after another oil change with treatment and 13,351 miles; and • 2.6% improvement in fuel economy after 20,993 miles.

This research was conducted using the TMC / SAE Type II test procedure. Two 2004 Freightliner Columbia Series Model C120 tractors served as the treatment and control vehicles, both powered with identical 435 BHP Detroit Diesel 14L Series 60 engines. The test was conducted on a 1.7 mile closed loop oval test track at Auburn University in Opelika, Alabama. The primary purpose of the track is to damage experimental pavements, but the highly controlled fleet operations create a unique opportunity to concurrently study vehicle performance.

The research fleet at the Pavement Test Track consists of 155,000 pound, 8 axle heavy triples. Speeds are limited to approximately 48 mph, which require the tractors to be driven in direct gear (1:1) with an engine speed of 1533 rpm. Cruise control is engaged when test vehicles have reached optimum speeds. The demand wheel horse power varies between 200 hp on the track’s ½ mile flat straight sections to 300 hp on the 1/3 mile long west end curve on a ½% grade. During testing, fuel consumption was measured in 50-gallon portable weigh tanks that accommodated 4 test runs on a single fill.

The weight of fuel consumed after each 30-mile run was measured on an Ohaus Champ II Model CH300R digital scale with a 650 pound capacity. Fuel temperature was measured at the end of each test run using a digital temperature probe. The same drivers remained with both the control vehicle and the treatment vehicle for the duration of testing. Two engine lube oil changes were made during testing in both vehicles. In each case, engine oil in the test vehicle was treated with DSX Extra.

No maintenance or operational problems of any type were noted as a result of the addition of the additive. Treatment of the lube oil in the engine, transmission and drive axles did not show an immediate short-term fuel economy improvement; however, an apparent improvement of 1.6% was observed after 13,351 miles (and two treated oil changes). Ultimately, a 2.6% improvement was observed after 20,933 miles of operation. Long-term impact on fuel economy improvement was not considered in this evaluation. The duty cycle for the test and control vehicles was (then) and is (today) 45 MPH in cruise control in two hour segments, with each driver working four segments and the vehicles working two shifts.

At 45 MPH in cruise control, the vehicles are operating dead center on the torque curve. That means the truck engines are running under optimal conditions. The report says with DSX Extra, we improved on optimal. This level of improvement was confirmed in a CAT 3456 GenSet which was also operating in the center of the torque curve. Our customers continue to report MPG improvements greater than the report. These customer reports are based on (1) miles driven and fuel in tank, (2) GPS and (3) engine management reports.

We have made no effort to test independently with delivery type vehicles. However, customers with Ford F150 and F350 pickup, Chevy and GMC 2500 pickups and Dodge 1500 and Dodge 3500 pickups have reported good MPG improvement from using DSX Extra in both the engine and differential. The differential application seems to be particularly interesting because the application appears to be once every year or two while the lowest reported improvement in MPG has been 1.0. View the entire report! Adobe PDF Format

TBN/TAN

Total Base Number. Testing a lubricant’s base number measures its alkaline reserve – or its ability to neutralize degradation acids. Although viscosity is more important, base number determines an oil’s suitability for continued use and is critical to safely extending drain intervals. A decrease in base number is typically accompanied by an increase in oxidation, nitration and viscosity. Sulfur from fuel and nitrogen from the air – when combines with water – form sulfuric and nitric acids that will attack engine metals causing wear that can eventually result in engine failure.

To combat combustion byproduct acids, diesel engines oils contain acid neutralizing additives – the most common being magnesium and calcium. New diesel engine oils typically have a starting base number between 8 and 12. It is generally recommended that diesel engine oil be changed when the Total Base Number is 50% that of the new oil. For example, an engine oil with a starting base number of 10 should be changed if the base number test result is less than 5.0 mg KOH/g. Total Acid Number. Engines fueled by natural gas operate at higher temperatures than diesel engines requiring lubricating oils with lower ash content. Higher temperatures cause metal sulfates in barium, magnesium, calcium and phosphorus-based additives to form engine deposits.

These ash deposits then cause valves to stick reducing engine efficiency. In addition, excessive concentrations of ash can form in glassy deposits on natural gas engine exhaust catalysts reducing their ability to control harmful emissions. Typical low ash natural gas engine oil has one third the amount of detergent and one fourth the amount of anti-ware additives as diesel engine oil which leaves them as vulnerable as diesel engines to the degradation acids produced by combustion. Testing for acid content and monitoring the rate at which these acids form become the objective in determining a natural gas engine oil’s suitability for continued use or safely extending drain intervals.

An increase in acid number is typically accompanied by an increase in oxidation, nitration and viscosity. The starting acid number of new oil is determined by the amount of acid present from additives. Typical new low ash or ashless natural gas engine oils have a starting acid number between 0.7 and 1.0 mg KOH/g. The general recommendation is to change the oil when the acids number is four times the acid number of the new oil. For example, a natural gas engine oil with a starting acid number of 1.0 mg KOH/g should be changed when the acid number test results is 4.00 mg KOH/g or greater.

TBN/TAN Oil Analysis Report 2011 Hyundai Genesis – April 2018

The oil analysis information on a 2011 Hyundai Genesis with a V-6 engine is as follows. When purchased, the vehicle had been serviced with Mobil 1 5W-20. Oil analysis was done according to the owners manual at the 7,500 mile oil change was needed based on starts/stops/etc. The first oil analysis with Mobil 1 was to establish a base line for further comparison. The second oil analysis was with Penzoil 5W-20 and 10% DSX Extra. The subsequent oil analyses were done with Penzoil 5W-20 and 5% DSX Extra.

The last three analysis were done with Penzoil 5W-20 and 5% DSX Extra at 10,000 miles. The important information is in the wear factors and the TAN. Note. The last oil analysis was done based on a scheduled service, not the usual computer determination. We understand that this is a gasoline engine; not a diesel engine. However, wear is still wear and acid is a function of the combustion process. Read the report! Adobe PDF

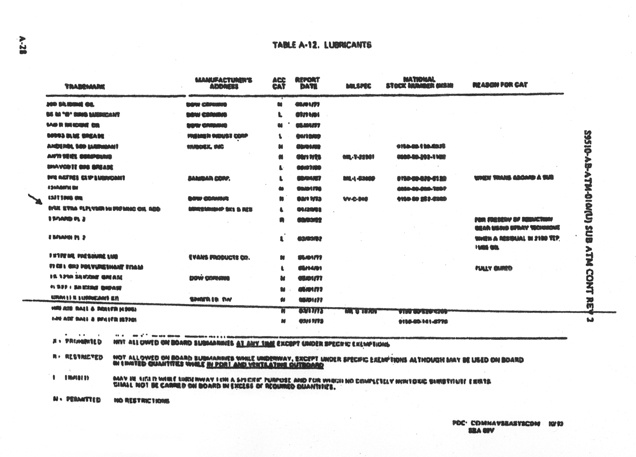

DSX Extra – Results – Seizure Test – U.S. Navy.

Our product information package includes two pages – the cover of the manual for U.S. Nuclear Submarines and a page showing DSX Extra as approved. In 2005, we contacted the U.S. Navy under the Freedom of Information Act to request copies of information developed during the testing process. It was our understanding that this test process took more than 1.5 years.

After reviewing our request, the U.S. Navy released considerable information. Unfortunately, most of the information was redacted because “the responsive documents contain recommendations, it is considered pre-decisional in nature, and serve as part of the deliberative process”, whatever that means. We are not sure how any of that applies to our request, but we did find something of interest, specifically, a Test Memorandum on Measurement of Extreme-Pressure Properties of Lubricating Greases and Oils with comments. Method.

Tester is operated with one steel ball under load rotating against three steel balls held stationary in the form of a cradle. Rotating speed and temperatures were set. Then the subject steel ball was subjected to a series of tests having a duration of 10 seconds at increasing loads until welding (seizure) occurs. Grease. Results. Load increased to 800 Kg (machine limit) with no weld. Liquid/Oil. Results. Load increased to 800 Kg (machine limit) with no weld. Comments.

Scar surfaces were exceedingly smooth and clear of scoring. In the Test Director’s seven years of experience, this is a first in terms of performance. The test was conducted by the FALEX Corp, Aurora, Illinois. From the information provided by the U.S. Navy, we were able to determine that DSX Extra was being tested for (1) running gear applications and (2) cylinder lubrication.